Motor Driven

Motor Operation

You often see motor operators in parking garages, distribution facilities, paint booths, and car washes. Motor operation is the most effective and consistent method of opening larger, higher cycle doors and offers the following benefits:

- Longevity: Offers the most consistent method of operation, and as such, maximizes door longevity

- Ease of Use: Can link to one-touch, or even no touch, opening triggers such as a push button station or a loop detector

- Safety: Accommodates entrapment devices such as photo eyes and sensing edges

- Remote Activation: Can be integrated into master building controls to operate doors remotely

- Durability: Can be designed to withstand weather, chemicals, or even explosions

NOTE: Motor operation does require power to the opening and enough clearance to mount the motor. In the event of a power outage, auxiliary operators can be used (push up or chain, depending on door size and configuration).

EuroDrive & APEX Pro SmartController™

This rolling door motor and advanced control system shipped with each door is specifically designed for reliability and longevity.

The advanced control system is a solid state, microprocessor-based control system. It represents the latest in rolling steel door drive technology and has been configured and set-up exclusively for each door. The APEX Pro SmartController™ is available across our full range of Extreme rolling products for streamlined and easy installation.

- Drive System

- Soft Stop and Soft Start Operation

- Advanced logic PCB control with variable frequency drive and graphic LCD screen

- NEMA Rating

- Obstruction Detection

- 24 V dc Outputs

- Auxiliary Outputs

Cycle Rating: 1,000,000 or 5 Years

Voltage: 120 V AC 1PH 60Hz*, 208/230 V AC 3PH 60Hz, 208/230 V AC 1PH 60Hz**, 460 V AC 3PH 60Hz

Direct Drive Operator with APEX Pro SmartController™

The motor and advanced control system shipped with each door is specifically designed for reliability and longevity when used as a rolling steel door operator. The hollow shaft motor unit features a direct drive gear reduced, emergency hand chain and a high efficiency motor and solenoid brake.

The advanced control system is a solid state, microprocessor-based control system. It represents the latest in rolling steel door drive technology and has been configured and set-up exclusively for each door.

- Drive System

- Soft Stop and Soft Start Operation

- Advanced logic PCB control with variable frequency drive

- NEMA Rating

- Obstruction Detection

- 24 V dc Outputs

- Auxiliary Outputs

Cycle Rating: 300,000 or 2 Years

Voltage: 120/1/60 V ac*, 230/1/60 V ac**, 208/230/3/60 V ac, 460/3/60 V ac, 575/3/60 V ac

Cookson EverGard Operator with Battery Backup

In the event of a power outage, the EverGard Operator has an integrated battery backup will allow the grille to operate up to 10 cycles in a 48 hour time period.It’s a UL listed, gear head DC operator rated for a maximum of 10 cycles per day. It features the following:

- Backup battery is used in the event of a power outage for a minimum of 48 hours and up to 10 cycles

- Rechargeable battery

- Programmable battery self testing

- Separate programmable control box and back-up power unit

- Control box can be installed up to 120 ft away from the monitor

- Remote monitoring diagnostics

- Totally Enclosed Non-Ventilated (TENV) motor

- Motor mounted interlock available to ½ HP

- Compact operator/mounting configuration

Cycle Rating: Rated for a maximum of 10 cycles per day.

HP: Factory will advise on minimum HP for specific door size and configuration

Volts: 120

See EverGard Operator Data Sheet

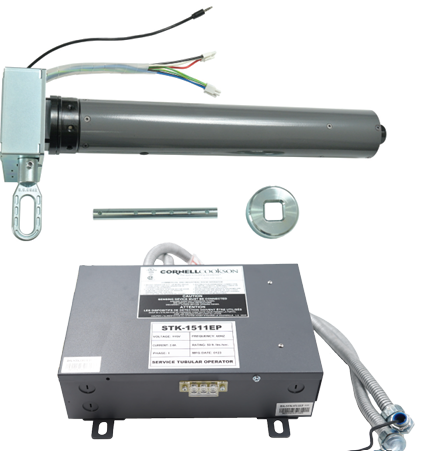

Cookson EverGard Tube Motor

The EverGard Tube Motor operator is ideal for openings with tight clearances around the coil area, when you need to neatly conceal the drive components without adding a bulky motor cover and for door control during a loss of power. It is available on counter doors, grilles and light gauge service doors (22 & 24 gauge). EverGard Tube Motor features the following:

- Totally enclosed Non-Ventilated (TENV) motor

- AC/DC input powers auto switching

- Auto-recharge battery

- In the event of a power outage, the integrated battery backup will allow operation for up to 10 cycles in a 48 hour time period

- UL325 listed

- Non-resettable cycle counter

- Programmable battery self testing

- Remote programmable control box comes standard with 12ft of cable

- Speed Governor to prevent free fall

- Programmable CONSTANT or MOMENTARY contact open and close

- Continuous monitoring sensing edge device ELR/IR connecting points

- Selectable "auto-open" or "stay in position" function if BBU reaches critically low voltage

- Selectable "auto-open" or "stay in position" function at AC power loss

- Abnormal power warning LED with selectable audible alert

- EverGard Tube Maximum Dimensions

Input Voltage: 120VAC

Activation Input: 24VDC

Phase: 1

Duty: 10 cycles/day

See EverGard Tube Motor Operator Sheet

EverGard Tube Operator Manuals

Tube Motor Operator

A concealed tubular motor offers a smaller, more compact motor design for counter shutters, fire shutters, grilles and gates. It is the ideal solution for strict dimensional limitations around the header, as it requires less clearance than standard motor operators. In addition, due to its reduced size, it is ideal for enhancing aesthetics.

Tube Motor Operator Features:

- Convenience of motor operation in a low profile, sleek design

- Easy to install and functionality consistent with our SGH operators

- Compact side room and light weight

- Improved daily cycle usage - 5 cycles/hour

- UL325 listed

- Available in 3" and 4" type motors to work with a wide range of door sizes

- Auxiliary hand crank for emergency operation

- Cycle counter

- Terminal connection for a monitored entrapment protection device

- Onboard open and close limit signaling connections

- 24 VDC warning output signal when the door is moving

- Onboard Open/Close/Stop buttons

- Close override if the entrapment protection device short circuits

Power Supply: 120V 60Hz

Duty: 5 - 10 cycles/hour

Cookson SGH Motor Operator

Our SGH motor is our super duty motor operator. It’s a UL listed, gear head operator designed for continuous, higher cycle use that exceed 20 cycles per day. It features the following:

- Totally Enclosed Fan Cooled (TEFC) motor

- Factory pre-wired motor control terminals

- Maintenance free, solenoid actuated brake

- Overload protection

- Lubricated, heavy-duty gears

- Compact operator / mounting configuration

- Fully adjustable, driven linear screw type cam limit switch mechanism

- Auxiliary manual chain hoist for emergency operation provided up to 2 HP as standard. Auxiliary chain hoist automatically engages when motor is not energized - just pull to operate

Cycle Rating: designed for continuous use.

HP: Factory will advise on minimum HP for specific door size and configuration

Voltage: 115, 208/230, 460 and 575

Cookson MG Operator

Our MG motor is our industrial duty motor operator. It’s a UL listed, gear head operator rated for a maximum of 20 cycles per day. It features the following:

- Totally Enclosed Non-Ventilated (TENV) motor

- Motor mounted interlock available to 1/2 HP

- Factory pre-wired motor control terminals

- Maintenance free, solenoid actuated brake

- Overload protection

- Lubricated, heavy-duty gears

- Compact operator / mounting configuration

- Fully adjustable, driven linear screw type cam limit switch mechanism

- Auxiliary manual chain hoist for emergency operation or provisions for auxiliary push-up operation is available. Auxiliary chain hoist safely cuts operator power when engaged: just pull to operate

Cycle Rating: Rated for a maximum of 20 cycles per day.

HP: Factory will advise on minimum HP for specific door size and configuration

Volts: 115, 208/230, 460 and 575.

Waterproof Series SGH Operator

Our Waterproof SGH Operator comes with all of the same great features as our SGH operator plus:

- Designed to meet requirements for NEMA 4/12 or NEMA 4X applications.

- Suitable for low pressure direct spray.

- The 4X series comes with a stainless steel finish which makes it corrosion resistant.

Cycle Rating: Designed for continuous use.

HP: Factory will advise on minimum HP for specific door size and configuration

Volts: 115, 230, 460 and 575

Indirect Splash-Proof MG Operator

Our Indirect Splash-Proof MG Operator comes with all of the same great features as our MG operator plus:

- Designed to meet requirements for NEMA 3R applications.

- Splash-proof for indirect contact.

Cycle Rating: Rated for a maximum of 20 cycles per day.

HP: Factory will advise on minimum HP for specific door size and configuration

Volts: 115, 230, 460, 575

NEMA 7/9 Operator

Built with the same reliable features as the FireGard NEMA 7/9 Motor Operator FHN79/FGN79 and available for retrofit, this operator comes with these optional features:

- Multiple sensing devices

- Intrinsically safe board

Cycle Rating: Designed for continuous use.

HP: Factory will advise on minimum HP for specific door size and configuration

Volts: 115, 230, 380, 460, and 575